As sustainability becomes increasingly important, understanding how to calculate the carbon footprint of electric motors is crucial. Do you know how to determine the COâ‚‚ emissions from your electric motors, and which types of motors are more environmentally friendly?

To calculate a motor’s CO₂ emissions, you’ll need two key pieces of information:

1. Power consumption (in kWh)

2. CO₂ base emission coefficient (kg CO₂/kWh) – provided by your electric power supplier.

Using the following formula, you can estimate a motor's COâ‚‚ emissions:

**■Formula for Calculating a Motor’s CO₂ Emissions**

Motor’s CO₂ emissions (kg CO₂)

= Motor's power consumption (kWh) × CO₂ base emission coefficient (kg CO₂/kWh)

Please reach out to your nearest branch or sales office or contact our customer support team for detailed power consumption figures for combinations of AC motors and inverters or brushless motors.

The CO₂ base emission coefficients provided by electric power suppliers are based on the "List of Base Emission Coefficients by Electric Power Supplier" published by Japan’s Ministry of the Environment and Ministry of Economy, Trade, and Industry. For other countries, you may need to look up this information, but in the U.S., power plants are required to provide such data.

For example, let’s consider a 200 W AC motor combined with an inverter (VFD). Using the formula above, the annual CO₂ emissions would amount to approximately 521 kg CO₂.

**Power consumption (1,109 kWh/year) × CO₂ base emission coefficient (0.470 kg CO₂/kWh) = CO₂ emissions (~521 kg CO₂)**

**Conditions:**

-Calculated with 12 hours of operation per day, 300 operating days per year, and a COâ‚‚ base emission coefficient of 0.470 kg COâ‚‚/kWh.

-This example refers to a standard 200 W output BH Series 3-phase AC induction motor paired with an inverter (VFD).

However, if you’re looking for even better efficiency, a brushless (DC) motor might be worth considering.

Switching to a brushless motor with the same 200 W output could reduce the annual CO₂ emissions to around 386 kg CO₂ under the same conditions. That’s approximately 25% less than an AC motor!

**Power consumption (821 kWh/year) × CO₂ base emission coefficient (0.470 kg CO₂/kWh) = CO₂ emissions (~386 kg CO₂)**

**Conditions:**

-Calculated with 12 hours of operation per day, 300 operating days per year, and a COâ‚‚ base emission coefficient of 0.470 kg COâ‚‚/kWh.

-This example refers to a 200 W output BMU Series brushless motor.

Here’s a quick comparison:

| **Type** | **Power Consumption (kWh/year)** | **COâ‚‚ Emissions (kg COâ‚‚/year)** |

|----------------------|---------------------------------|---------------------------------|

| AC Motor + Inverter | 1,109 | 521 |

| Brushless Motor | 821 | 386 |

This means that replacing a 200 W AC motor and inverter (VFD) with a brushless motor system of equivalent specifications can reduce COâ‚‚ emissions by 135 kg COâ‚‚ annually. To put that into perspective, this reduction is roughly equivalent to the COâ‚‚ emissions of one refrigerator per year.

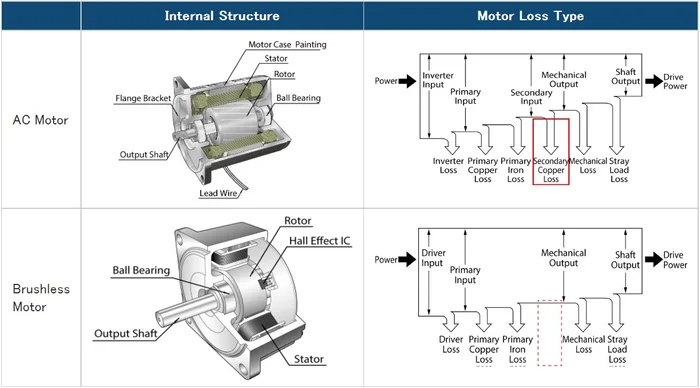

**Why are brushless motors more efficient?**

Brushless motors use permanent magnets to enhance magnetic flux, resulting in lower losses compared to AC motors. One major advantage is the absence of secondary copper losses, making them highly efficient and allowing them to perform the same tasks using less power. Higher efficiency also means smaller and lighter motors, contributing to resource conservation.

By the way, electrically commutated (EC) fans with integrated brushless motors can also play a role in saving energy. When comparing speed control technologies, brushless motors offer numerous benefits over AC motors.

**Takeaways:**

- A motor’s CO₂ emissions can be calculated by multiplying its power consumption (kWh) by the CO₂ base emission coefficient (kg CO₂/kWh).

- High-efficiency, energy-saving brushless motors are an excellent choice for reducing COâ‚‚ emissions.

- Switching from an AC motor to a brushless motor can reduce annual COâ‚‚ emissions by the equivalent of one refrigerator.

To learn more about products that can help reduce energy consumption and carbon emissions, visit our carbon neutrality page.

For a consultation on achieving carbon neutrality, consider scheduling a technical seminar.

---

I hope this gives you a clearer understanding of how to calculate COâ‚‚ emissions from electric motors and why brushless motors are a greener option. Let me know if you have any questions or need further details!

Curtain Jacquard Fabric Machine

All the electronic jacquard machines under this curtain jacquard fabric machine classification could weave various of patterns stably and sufficiently . These jacquard looms are applicable to various of textile weaving looms, such as rapier loom, air jet loom, water jet loom, shuttle loom, projectile loom with any reed width. These digital jacquard machines are compatible with most brand of textile weaving machinery, just like ITEMA, SOMET, SMIT, PICANOL, DONIER, RIFA, TOYOTA, TSUDAKMOA etc.

Curtain Jacquard Fabric Machine ,Jacquard Loom,Jacquard Machine,Computerized Jacquard Machine

JIANGSU S&S INTELLIGENT SCIENCE AND TECHNOLOGY CO., LTD , https://www.ssjacquard.com