Site Bite: Replacing the Coil in a Liebert® Condensing Unit

Join Chris Wright, a Chicago-area Account Manager, as he heads to the P&W Foundry for a high-pressure job that required quick action and precision.

Recently, we were called to an urgent job at the P&W Foundry in Plano, IL, to build a replacement coil for a Liebert® condensing unit. This was no ordinary repair — the unit was responsible for cooling a production floor that manufactured time-sensitive parts for the U.S. Navy. With no room for downtime, we knew we had to act fast.

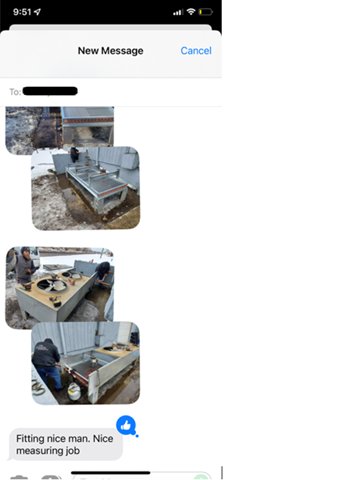

As the unit wasn’t being replaced, it was crucial to match the coil’s circuitry, fin density, and piping connections exactly to ensure a direct replacement. The coil was large but accessible, making the sizing process straightforward. We arrived on the same day we received the call and started measuring right away.

The coil had some non-standard features, which I've seen before in the field. The copper connections extended from the bottom of the headers, so we had to replicate their exact placement for a smooth field changeout. Additionally, the flanges were built uniquely, requiring an extra bend on each of the entering air-side plate flanges to provide better stability on the four pillars the coil rested on.

With detailed sketches and notes, we made all the customizations precisely. The customer had a tight 5-day production schedule, and the installation went off without a hitch. Within a week, they were fully back online and very satisfied with the performance of the new coil.

Written by: Chris Wright

Nationwide Coils Account Manager, Chicago

Led Boat Trailer Lights,Led Trailer Tail Lights,Submersible Led Trailer Lights,Boat Trailer Tail Lights

Taishan Yuanjin Auto Parts CO., LTD , http://www.tsyuanjin.com