Texo Case Study: Tank Inspection on an FPSO

TEXO maximizes value by using Elios drones, offering precise location referencing, detailed point clouds, and eliminating the risks associated with confined space entry. Discover how this technology is transforming oil tank inspections!

Key Benefits at a Glance

|

Savings Traditional tank inspections require 4–5 rope access technicians who must wait for tanks to be emptied and cleaned before they can begin. The process typically takes 7–10 days, leading to high labor costs and significant production downtime. With Elios 3, only two people are needed for 2 days per tank, significantly cutting both labor and production loss. |

Speed Conventional methods can take up to 10 days per tank, but Elios 3 reduces this to just 2 days. Inspectors can prioritize high-risk areas first, enabling faster identification of issues and quicker maintenance planning. |

|

Safety Oil tank inspections pose serious risks, requiring technicians to work at height for extended periods. Using Elios, pilots remain safely on the ground, avoiding dangerous confined spaces entirely. |

Operations Drone inspections only require two personnel, reducing the need for bed space compared to traditional rope access teams. This is especially valuable on FPSOs, where crew space is limited and must be used efficiently. |

Introduction

Floating Production, Storage, and Offloading (FPSO) vessels provide flexible and efficient infrastructure for offshore oil operations. These large ships process and store crude oil until it can be offloaded via tanker or pipeline. They are easy to install and can be relocated as needed to optimize production portfolios.

Despite their high initial cost, FPSOs have a long operational lifespan due to their adaptability. Typically, processing equipment is located above deck, while storage tanks are situated below in the double hull. A typical FPSO carries a crew of 50–70 people, and regular inspections are required for safety and compliance.

Customer Needs

TEXO was tasked with inspecting oil tanks on an FPSO. While dry dock inspections are manageable with scaffolding and large teams, in-station inspections are far more complex. Tanks cannot all be emptied at once due to balance and operational constraints, so only two are usually available at a time. Preparing them for inspection can take weeks, and waiting for deployment can lead to delays.

Rope access inspections are not only time-consuming but also risky. In some cases, scaffolding is needed, which adds further danger and potential damage to the tank’s structure. Labor costs are high, but even more costly is the production downtime during the inspection period. Engineers must check for cracks, distortions, and other defects, often in hard-to-reach areas like toe wells.

Solution

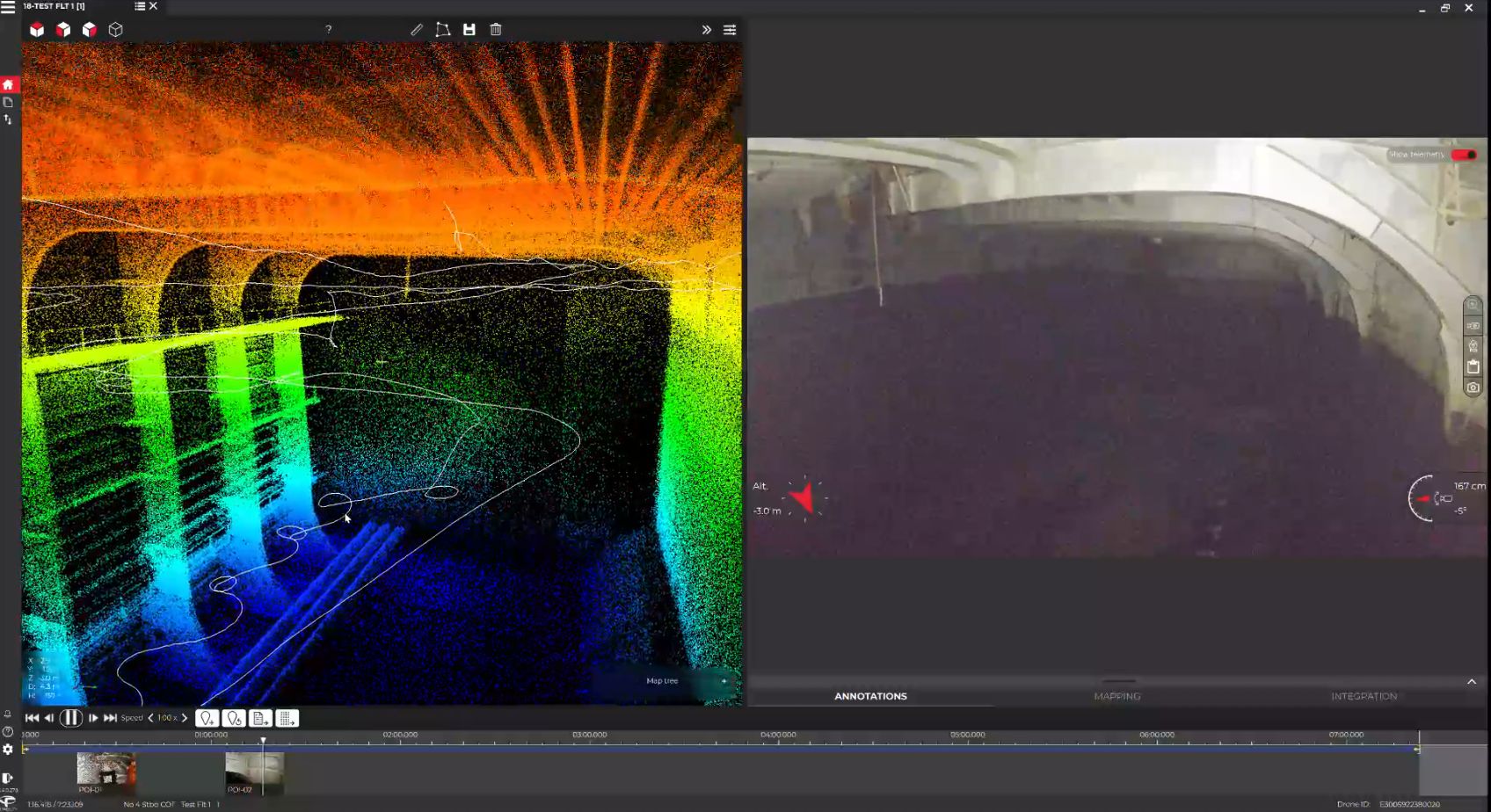

TEXO used the Elios 3 to inspect the oil tanks in just one week after cleaning and emptying. The team consisted of only two people, with the pilot operating the drone from outside the tank. Four flights were conducted, generating a complete 3D point cloud of the tank.

According to TEXO’s Xiang Wong, “Elios is such a good tool that it only requires two people instead of five for several days.†He added, “It gives onshore surveyors confidence that the entire tank has been inspected thoroughly. The flight trajectory ensures no area is missed.â€

Compared to rope access, where inspectors rely solely on visual confirmation, Elios provides video continuity and trackable data. “Multiple inspectors can review the same dataset and add their own expertise,†said Wong. “This leads to better decision-making and more accurate results.â€

The Elios 3 also helps in identifying critical areas quickly. “We can inspect hot spots or stress points first, allowing us to address issues early and plan repairs while the tank is still empty,†explained Wong.

One particularly challenging part of the tank is the steam heating coils, which are fragile and difficult to inspect manually. The Elios 3’s collision-resistant design allows it to fly complex patterns and generate a detailed point cloud. This data can then be combined with topside information for a full view of the tank, helping engineers plan repairs accurately.

Results

TEXO delivered a highly accurate inspection with detailed point cloud data, which had never been available before. The process took only 4 days, much faster than the usual 2-week timeline. The client was very satisfied and expressed interest in using Elios for future FPSO inspections.

The inspection was completed without any risk to personnel, and onshore teams gained full confidence that every area had been covered. The ability to revisit data multiple times also improved overall accuracy and efficiency.

Conclusion

TEXO sees great value in using the Elios solution for various oil and gas inspection projects. They’ve used both the Elios 2 and Elios 3, but emphasize the benefits of location referencing and point cloud generation with the latest model. “Elios 2 is great for basic inspections, but for problem-solving, Elios 3 is essential,†said Xiang Wong.

Looking ahead, TEXO plans to explore new applications, including semi-submersible vessels. “These structures are like mazes to navigate,†Wong said. “Elios 3 is the perfect tool for that. It eliminates the need to send personnel into confined spaces, making inspections safer and more efficient.â€

TEXO Group is certified by DNV (Det Norske Veritas) as an approved service provider for remote inspection techniques (UAVs), offering an alternative to close-up surveys of ship structures and mobile offshore units.

Commercial grinder, Stainless Steel Grinder, one-click grinder, Touch LED grinder, big capacity grinder

Heshan Zilong Home Appliance Technology CO.Ltd , https://www.techonele.com