Common Uses of 321H Stainless Steel Flats in Industrial Settings

Thanks to their remarkable properties, 321H stainless steel flats are a vital material in many industrial applications. Known for their high-temperature resistance, corrosion resistance, and durability, these flat products are used across various sectors. This article delves into the most common uses of 321H stainless steel flats in industrial environments, showcasing their advantages and practical applications.

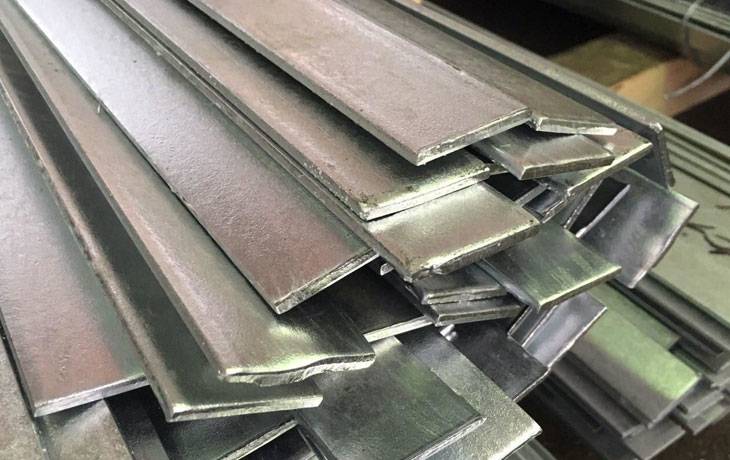

Understanding 321H Stainless Steel Flats

321H stainless steel is an austenitic alloy containing chromium, nickel, and titanium. It’s specifically designed to withstand high temperatures and resist oxidation, making it ideal for challenging conditions. 321H stainless steel flats are flat-rolled versions of this alloy, widely used in different industrial fields due to their versatility and performance.

Key Properties of 321H Stainless Steel Flats:

- High-Temperature Resistance: These flats can operate effectively at temperatures up to 1500°F (815°C).

- Corrosion Resistance: The alloy provides excellent resistance to oxidation and corrosion.

- Structural Stability: Titanium stabilizes the steel, preventing carbide precipitation and improving performance at elevated temperatures.

-

Aerospace Industry

In the aerospace sector, 321H stainless steel flats are highly valued for their ability to perform under extreme conditions.

- Aircraft Components: Used in aircraft exhaust systems and other high-temperature parts where thermal stability and strength are essential.

- Engine Parts: Components exposed to high heat and stress benefit from the alloy's durability and corrosion resistance.

The aerospace industry relies heavily on 321H stainless steel flats to ensure performance and safety in critical applications.

-

Chemical Processing

Chemical processing involves handling aggressive chemicals and high temperatures, making 321H stainless steel flats an excellent choice.

- Reaction Vessels: Used in vessels and equipment that resist corrosion and withstand high temperatures.

- Piping Systems: Ideal for piping where chemical resistance and thermal stability are crucial.

Using 321H stainless steel flats in chemical processing ensures equipment remains functional and reliable, even in harsh environments.

-

Oil and Gas Industry

The oil and gas industry requires materials that can endure severe conditions, and 321H stainless steel flats meet those demands.

- Drilling Equipment: Used in drilling tools and components that face high pressure and temperature.

- Pipeline Construction: The alloy’s resistance to corrosion and high temperatures makes it suitable for pipelines and maintenance.

In the oil and gas industry, 321H stainless steel flats provide the strength and durability needed for challenging applications.

-

Power Generation

In power generation, where equipment operates at high temperatures and is exposed to various elements, 321H stainless steel flats offer significant benefits.

- Boiler Components: Used in boiler parts that must withstand high heat and pressure.

- Turbine Parts: Turbine components made from 321H stainless steel benefit from its thermal stability and resistance to degradation.

321H stainless steel flats play a key role in power generation, contributing to the efficiency and longevity of critical components.

-

Automotive Industry

The automotive industry uses 321H stainless steel flats for various components requiring high strength and environmental resistance.

- Exhaust Systems: Used in exhaust systems where high-temperature resistance and durability are necessary.

- Engine Parts: Components exposed to high stress and heat benefit from the enhanced performance of 321H stainless steel.

The automotive industry relies on 321H stainless steel flats to ensure reliable performance under demanding conditions.

-

Marine Applications

Marine environments present unique challenges, including exposure to saltwater and high temperatures. 321H stainless steel flats are well-suited for these conditions.

- Shipbuilding: Used in ship components that must resist corrosion and withstand the marine environment.

- Offshore Equipment: The alloy’s resistance to oxidation and saltwater makes it ideal for offshore structures and equipment.

The marine industry depends on 321H stainless steel flats for their ability to withstand harsh conditions and ensure long-lasting performance.

Conclusion

321H stainless steel flats are essential in multiple industrial applications thanks to their high-temperature resistance, corrosion resistance, and overall strength. From aerospace and chemical processing to oil and gas, power generation, automotive, and marine industries, these flats deliver critical benefits that enhance performance and durability.

Investing in 321H stainless steel flats ensures reliable and efficient operation across various industrial settings, highlighting their versatility and importance. Their unique properties make them an excellent choice for demanding applications that require superior material performance.

Special Shape Packaging,Plastic Food Packaging Film,Bopa Plastic Membrane Packaging,Plastic Membrane Bopa Packaging

HUARUIDA PACKING MATERIAL CORP., LTD. , https://www.buybopps.com