Preventive Maintenance: A Guide

Preventive maintenance involves a series of routine procedures aimed at reducing equipment failures and unplanned downtime. These practices play a crucial role in maintaining operational efficiency and minimizing disruptions.

Preventive maintenance encompasses activities such as inspections, lubrication, and belt adjustments. Alongside these manual upkeep tasks, it also involves meticulous planning, scheduling, and documentation of past inspections and service reports. Companies utilizing heavy machinery frequently adopt preventive maintenance strategies to avoid unexpected breakdowns and enhance productivity. Industries like oil and gas, manufacturing, and mining commonly rely on these methods.

What Is Preventive Maintenance?

Preventive maintenance refers to scheduled routines conducted at predetermined intervals to lower the risk of equipment failure. These activities may include inspections, cleanings, part replacements, and minor repairs. The ultimate goal is to ensure equipment operates consistently with the manufacturer's specifications. Such plans also aim to reduce workplace accidents, unplanned downtime, and repair costs.

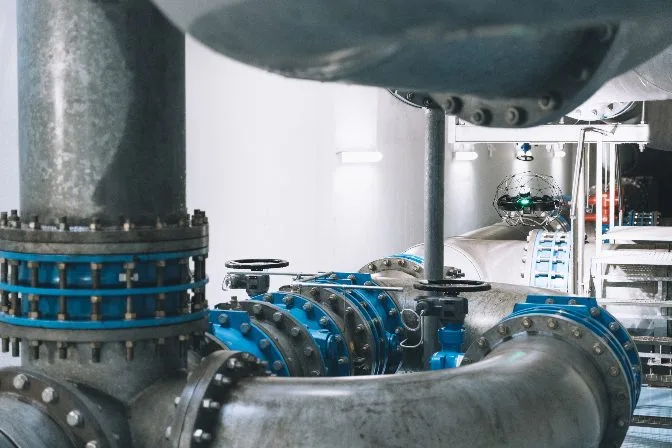

The Elios 3 drone inspecting a water management system

The Elios 3 drone inspecting a water management system

Why Is Preventive Maintenance Important?

Implementing preventive maintenance brings numerous advantages to businesses, primarily enhancing efficiency and cutting costs. Key benefits include reduced equipment downtime, improved worker safety, and adherence to regulatory standards.

The expense of preventive maintenance is generally much lower than that of reactive maintenance, which addresses issues only after they arise. Reactive maintenance, or run-to-failure (RTF) maintenance, tends to incur higher costs and longer downtime periods. Regular checks on equipment prevent mechanical failures before they happen, enabling companies to adopt a proactive approach rather than reacting to crises.

When planning budgets for the upcoming year, preventive maintenance can serve as a pivotal element within a broader strategic budget framework. This allows organizations to develop comprehensive plans aligned with future objectives.

Advantages of Preventive Maintenance

Preventive maintenance procedures are designed to prevent problems from occurring in the first place.

Here’s a closer look at some of the reasons why preventive maintenance is essential:

Reduces Downtime

When machines operate optimally thanks to preventive maintenance, the chances of unplanned downtime affecting operations diminish significantly. Unplanned downtime can be extremely costly for businesses, particularly when it disrupts production. According to a report by Aberdeen Strategy and Research, unplanned equipment downtime can cost firms approximately $260,000 per hour in lost revenue. Moreover, such incidents can strain client relationships, leading to further financial losses over time.

Although unavoidable at times, proper preventive maintenance practices help guarantee that any equipment downtime is safe, scheduled, and predictable.

Extends Equipment Lifespan

Preventive maintenance not only minimizes downtime but also extends the lifespan of machinery. Regular inspections and servicing extend the overall durability of assets, reducing resource wastage and ensuring full utilization before retirement.

By extending equipment lifespans through preventive maintenance schedules, companies can delay purchasing new machinery, freeing funds for other critical business needs.

An inspector recording the operation of oil and gas processes

Improves Worker Safety

Assets functioning correctly as intended by manufacturers inherently make workplaces safer. Preventive maintenance ensures consistent asset performance, reduces failures, and minimizes accidents.

Equipment lacking regular preventive maintenance can fail catastrophically, resulting in various potential workplace injuries. Thus, preventive maintenance enhances worker safety and, in certain cases, even saves lives. Fewer accidents also translate into lower insurance premiums and workers' compensation claims.

Furthermore, preventive maintenance is far safer compared to alternative approaches like RTF maintenance. Exposing workers to hazards caused by failing assets poses greater risks than having them conduct scheduled preventive tasks earlier in time.

Ensures Regulatory Compliance

Most industries have regulations mandating preventive maintenance on assets. Failure to comply can result in fines or other penalties.

Adhering to regularly scheduled preventive maintenance guarantees compliance and shields companies from fines. By confirming that all machinery operates correctly, businesses meet regulatory standards.

Limitations of Preventive Maintenance

To achieve maximum effectiveness, preventive maintenance should be integrated into a broader maintenance strategy focusing on worker safety and preventing equipment failure.

Despite these limitations, preventive maintenance remains one of the best maintenance plans for companies seeking to prolong asset life.

Success Rate

Preventive maintenance reduces the likelihood of equipment failure but cannot eliminate it entirely. Accidents, natural disasters, and unforeseen circumstances remain challenging to account for fully.

Technological Constraints

While some assets feature sensors and gauges aiding in preventing mechanical failure, others rely solely on scheduled inspections. Predictive maintenance, leveraging complex calculations and algorithms to forecast failure points, proves more effective than conventional preventive methods.

Upfront Costs

Although less expensive than reactive or predictive maintenance, preventive maintenance entails initial expenses. Smaller businesses or those with constrained budgets might struggle to finance all necessary preventive maintenance activities, including planned downtimes.

Changing a car filter

Changing a car filter

Time Constraints

Preventive maintenance demands time. Occasionally, an asset must be shut down entirely for inspection or maintenance, impacting production goals. Finding time for these tasks becomes particularly challenging in companies with limited resources and personnel.

Staff Limitations

Most preventive maintenance initiatives require additional staff or extended hours for existing employees. Proper inspections and maintenance necessitate more resources.

Over Maintenance

Wasted resources, both in terms of time and money, could occur if a preventive maintenance plan allocates efforts toward unnecessary precautions. Historical data should guide adjustments to the plan while maintaining a regular schedule.

What Are the Types of Preventive Maintenance?

Three primary types of preventive maintenance exist:

- Time-based maintenance

- Usage-based maintenance

- Condition-based maintenance

Time-Based Maintenance

Time-based maintenance, also known as calendar-based maintenance, involves completing tasks at fixed intervals. This is among the most common types of preventive maintenance.

Changing air filters in climate-controlled environments exemplifies time-based maintenance since they usually require replacement every three months.

Time-based maintenance requirements often originate from manufacturers and can follow weekly, monthly, quarterly, or yearly schedules, depending on the asset. Historical records are vital for identifying which equipment requires extra attention.

The main drawback lies in the possibility of over-maintenance. Consider a filter recommended for replacement every three months. For heavily trafficked areas, this timing might be appropriate, but for low-traffic warehouses or factories, changing it so frequently could prove wasteful.

Cleaning a condenser tube from a chiller

Cleaning a condenser tube from a chiller

Usage-Based Maintenance

In usage-based maintenance, maintenance checks are triggered by tracking a machine's usage metrics. Unlike time-based approaches, usage-based maintenance focuses on actual usage rather than elapsed time.

Usage metrics may include cycle counts, mileage, operating hours, or runtime. An excellent illustration is preventive maintenance done on automobiles after reaching a specific mileage threshold, such as tire rotations or transmission checks.

Usage-based preventive maintenance prevents over-maintenance by ensuring that lightly used equipment doesn’t consume resources meant for more frequently utilized machinery.

Condition-Based Maintenance

Condition-based preventive maintenance depends on monitoring an asset's actual state. Inspectors analyze this information to decide when repairs and other maintenance are needed.

Condition-based maintenance requires detailed knowledge of how an asset performs and recognizing when maintenance is necessary. Properly executed, it can be just as effective at preventing mechanical failure as other types of preventive maintenance.

Declining performance indicators typically prompt condition-based maintenance. These declines can be detected through several methods. Once conditions deteriorate, maintenance is scheduled to restore reliability.

Examples of monitored factors in condition-based maintenance include:

- Noise: Changes in a machine’s typical steady sound might signal the need for condition-based maintenance.

- Temperature: Faulty wiring or component failures can alter equipment temperatures, triggering preventive actions.

- Vibration: Pumps, motors, or compressors vibrating abnormally may indicate they require lubrication or another form of maintenance.

- Visual Inspection: Observing surface cracks or visible corrosion represents one of the simplest forms of condition-based maintenance.

Types of Preventive Maintenance Tasks

Within each type of preventive maintenance, specific tasks can be categorized based on their significance and urgency. These tasks may be time-based, usage-based, condition-based, or combinations thereof.

Types of preventive maintenance tasks include:

- Mandatory Tasks: These must be performed exactly as scheduled or promptly upon becoming due to avoid equipment failure. Examples include emptying waste containers or cooling particular equipment components nightly.

- Non-Mandatory Tasks: Although still vital, non-mandatory tasks can be postponed or rescheduled without immediately risking critical equipment failure. Surface inspections or specific component cleanings fall under this category.

- Pyramiding Tasks: If a scheduled task is missed and overlaps with another maintenance activity, it becomes a pyramiding task. In such cases, the person executing the new task should note the original missed maintenance and monitor its overdue status.

- Inspection Tasks: Some maintenance tasks, especially condition-based ones, require prior inspections. Here, the inspection and subsequent maintenance are separate, and the maintenance task should only commence after an inspector identifies any issues.

- Task-Oriented Tasks: Task-oriented preventive maintenance duties involve situations where maintenance can coincide with inspections. This approach reduces the time, money, and manpower spent on individual maintenance tasks.

What Is a Preventive Maintenance Checklist?

A preventive maintenance checklist outlines tasks, targets, and procedures to be carried out as part of a broader maintenance plan.

Preventive maintenance checklists are typically developed collaboratively with maintenance managers, field workers, inspection contractors, and regulatory bodies. Many industrial enterprises utilize preventive maintenance software to assist in creating, tracking, and documenting their checklists.

Benefits of a Preventive Maintenance Checklist

Like all aspects of preventive maintenance, checklists aim to boost efficiency, decrease downtime, and improve worker safety.

Other advantages of a well-crafted preventive maintenance checklist include:

- Reduced human error

- Enhanced diagnostics

- Faster inspections

- Targeted training

- Streamlined maintenance planning

- Consistent workplace operations

Preventive Maintenance Checklist Examples

Preventive maintenance checklists vary across industries and organizations but share common goals and principles.

Below are examples of preventive maintenance checklists in three distinct fields:

Building Interior Preventive Maintenance Checklist

- Look for visible signs of wear and tear

- Check for leaks

- Inspect for electrical, tripping, and falling hazards

- Examine toilet and shower conditions

- Test smoke and carbon monoxide detectors

- Verify fire alarm systems

- Inspect fire extinguishers and firefighting equipment

- Ensure doors operate correctly and exits are clear

- Check door locks and closures

- Mark work areas and walkways clearly

- Remove garbage from storage areas

- Search for signs of pests

- Inspect cart casters for wear

- Secure, organize, and label shelves

- Check electrical receptacle cover plates for tightness and damage

- Confirm timers and photocells are functional

Network and Data Systems Preventive Maintenance Checklist

- Review network security practices

- Identify immediate network security threats regularly

- Ensure employees adhere to safe practices like password security and proper email habits

- Change Wi-Fi and other network passwords at least twice annually

Semi-Truck Preventive Maintenance Checklist

- Perform standard safety checks

- Lubricate necessary components

- Inspect brakes

- Check lights

- Examine tire condition and inflation

- Top off fluids

- Adjust high-wear parts

Drones in Preventive Maintenance

Preventive maintenance can be executed in various ways, often starting with visual condition monitoring.

One of the fastest and most advanced methods to carry out preventive maintenance tasks involves using drones or unmanned aerial vehicles (UAVs).

Agile UAVs can greatly assist in all types of preventive maintenance. They aid in monitoring equipment status during condition-based inspections and can even autonomously perform certain time-based or usage-based preventive maintenance tasks.

In some instances, an asset doesn’t need to be shut down for a drone to complete a visual inspection, allowing production to continue. At other times, drones drastically reduce downtime by eliminating the need for scaffolding to conduct inspections.

In this Flyability case study, the Elios 3 drone equipped with a LiDAR sensor assists the City of Lausanne’s Water Department in planning, tracking, and implementing maintenance schedules. Real-time LiDAR maps keep tabs on assets over time, providing accurate wear-and-tear reports.

Drones cut costs and time associated with specific preventive maintenance tasks while keeping inspectors out of hazardous and confined spaces.

With no need to enter potentially malfunctioning machinery zones, workers stay safer using Flyability’s Elios drones.

An Elios 3 drone performing a visual inspection

An Elios 3 drone performing a visual inspection

Cast Round Link Kiln Chains are mainly used for rotary cement kiln. Cast round link chains are manufactured by investment casting, which ensure high quality. Cast round link kiln chains can be produced by many kinds of materials according to customers' demands, such as Ni-Cr Alloy Round Cast Kiln Chains, Carbon Steel Round Cast Kiln Chains, etc.

Cast Round Link Kiln Chain,Heat Resistant,Cast Kiln Chains,Cast Round Chains For Cement

Jilin Huanyu New Materials Manufacturing Co., Ltd , https://www.huanyufoundry.com