When choosing between different types of tubing, several factors must be considered. Below is a detailed table that will help you understand the differences between welded and seamless tubing.

Table of contents

- What is Seamless Tube

- What is Welded Tubes

- Pressure Capacity of Seamless And Welded Tubing

- Seamless vs Welded Tubing

- Difference Between ERW and Seamless Tube Price

- Advantages and Disadvantages of seamless and welded tube

- Seamless Tubing Sizes

- Seamless Steel Tubes Manufacturing Process

- Welded Steel Tube Manufacturing Process

- Seamless Tubing vs DOM Tubing

- Seamless Steel Tube Uses

- Application for Welded Round Tubing

- Mechanical Properties of ERW vs Seamless Tube

- Finish for Welded and Seamless Tubes

- Seamless Tube Weight Chart

- SMLS Tube Extrusion Process

- Welded Tube Types

What is Seamless Tube

| Seamless tube meaning | A seamless, weld-free metal tube manufactured by heating a solid billet into the desired shape and form. |

| Seamless Tube Production Process |

|

| Characteristics |

|

What is Welded Tubes

| Definition | A metal tube created by joining the edges of a metal plate or strip to create a tube structure. |

| Production Process |

|

| Characteristics |

|

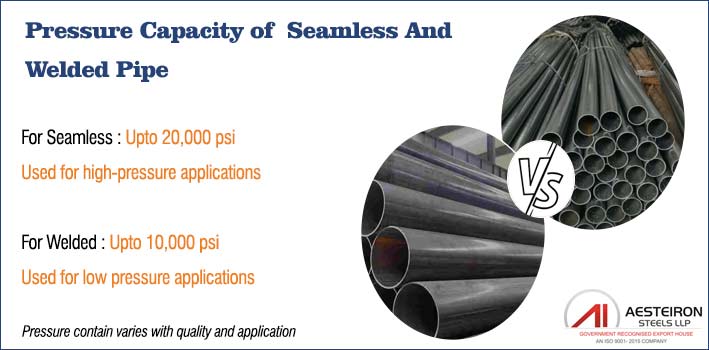

Seamless tubes can handle higher pressure than welded tubing

Because there's no weld in a seamless tube, it has no weak spot. This means that seamless tubes are generally stronger and can withstand higher pressure than welded tubes. Here's a detailed look at their pressure ratings.

Pressure Capacity of Seamless And Welded Tubing

Welded tubes often have larger diameters and thinner walls

This feature makes them ideal for architectural and construction applications where precise dimensions are needed. Since they can be produced faster, they're easier to customize for specific needs, allowing for larger diameters and thinner walls in specialized projects.

Seamless vs Welded Tubing

| Description | Seamless Tubing | Welded Tubing |

|---|---|---|

| Manufacturing Process | Seamless tubes are made from a solid billet that is heated and extruded to form a tube without any weld seam. | Formed from flat strips of metal that are rolled and welded along the length. |

| Length | Shorter in length | Long continuous lengths |

| Strength | Stronger | Lower compared to seamless |

| Uniformity | More uniform wall thickness | Wall thickness may vary slightly |

| Applications | Used for high-pressure applications and critical structural components. | Commonly used in less critical applications |

| Corrosion Resistance | More corrosion-resistant. | Less corrosion resistance. |

| Cost | More expensive | Less expensive |

| Manufacturing Flexibility | Less flexible | More flexible |

| Surface Quality | Rough because of extrusion process | Smooth high-quality surface |

| Surface Finish | Smoother finish and few surface defects. | Surface finish can be less consistent due to the welding process |

| Ovality | Provide better ovality and roundness | Â Poor ovality and roundness |

| Inspection & Testing | Requires more rigorous testing to ensure quality and strength. | May require less rigorous testing |

| Internal surface check | Not possible | Checked before manufacturing |

| Size Range | Available in a more limited range of sizes than welded tubing. | Can be produced in a large range of sizes and lengths. |

Welded tubing is generally less expensive than seamless tubing

Since welded tubes can be manufactured quickly, they are more adaptable than seamless pipes. This allows for more production in a given time, which reduces labor costs. It’s an excellent choice for industries requiring low to medium pressure applications.

Difference Between ERW and Seamless Tube Price

| Seamless Tube | ERW Steel Tube |

|---|---|

| More expensive: can be 1.5 to 3 times the cost of welded tubes | Less expensive: more affordable by 30% to 60% compared to seamless tubes |

| Factors affecting: Manufacturing Process, Quality, Production Costs, Demand | |

Advantages and Disadvantages of seamless and welded tube

The Pros and Cons of Hot Finished Seamless Type Tubes

| Pros | Cons |

|---|---|

| Excellent corrosion resistance | Expensive |

| Good Durability | Difficult to manufacture |

| High pressure rating | Not ideal for thin wall large diameter tubes |

| Good Purity | Longer lead times |

| Ideal for critical applications | Â |

The Pros and Cons of Welded Tubes

| Pros | Cons |

|---|---|

| Better lead times | Suitable for Heavy wall applications |

| Less Expensive | Less corrosion resistant |

| Available in long lengths | Slight impurities |

| Thinner wall | Stress concentration |

| More consistent concentricity | Â |

| Tighter tolerances | Â |

Seamless Tubing Sizes

| NPS | Schedule | DN | OD | Wall thck | Weight |

|---|---|---|---|---|---|

| [inch] | [inch] | [lbs/ft] | |||

| 1/8 | 10 | 6 | .405 | .049 | .19 |

| Â | 40 | Â | Â | .068 | .24 |

| Â | 80 | Â | Â | .095 | .31 |

| 1/4 | 10 | 8 | .54 | .065 | .33 |

| Â | 40 | Â | Â | .088 | .42 |

| Â | 80 | Â | Â | .119 | .54 |

| 3/8 | 10 | 10 | .675 | .065 | .42 |

| Â | 40 | Â | Â | .091 | .57 |

| Â | 80 | Â | Â | .126 | .74 |

| 1/2 | 5 | 15 | .84 | .065 | .54 |

| Â | 30 | Â | Â | .095 | .76 |

| Â | 40 | Â | Â | .109 | .85 |

| Â | 160 | Â | Â | .188 | 1.31 |

| 3/4 | 5 | 20 | 1.05 | .065 | .69 |

| Â | 30 | Â | Â | .095 | .97 |

| Â | 80 | Â | Â | .154 | 1.47 |

| Â | 160 | Â | Â | .219 | 1.94 |

| 1 | 5 | 25 | 1.315 | .065 | .87 |

| Â | 10 | Â | Â | .109 | 1.41 |

| Â | 40 | Â | Â | .133 | 1.68 |

| Â | 160 | Â | Â | .25 | 2.84 |

| 1 1/4 | 5 | 32 | 1.66 | .065 | 1.11 |

| Â | 30 | Â | Â | .117 | 1.93 |

| Â | 80 | Â | Â | .191 | 3 |

| Â | 160 | Â | Â | .25 | 3.76 |

| 1 1/2 | 5 | 40 | 1.9 | .065 | 1.28 |

| Â | 10 | Â | Â | .109 | 2.09 |

| Â | 40 | Â | Â | .145 | 2.72 |

| Â | 80 | Â | Â | .2 | 3.63 |

| Â | 160 | Â | Â | .281 | 4.86 |

| 2 | 5 | 50 | 2.375 | .065 | 1.61 |

| Â | Â | Â | Â | .109 | 2.64 |

| Â | Â | Â | Â | .141 | 3.36 |

| Â | 40 | Â | Â | .154 | 3.65 |

| Â | Â | Â | Â | .188 | 4.39 |

| Â | 80 | Â | Â | .218 | 5.02 |

| Â | Â | Â | Â | .281 | 6.28 |

| Â | 160 | Â | Â | .344 | 7.46 |

| 2 1/2 | 5 | 65 | 2.875 | .038 | 2.47 |

| Â | 10 | Â | Â | .12 | 3,53 |

| Â | Â | Â | Â | .125 | 3.67 |

| Â | Â | Â | Â | .156 | 4.53 |

| Â | Â | Â | Â | .188 | 5.4 |

| Â | 40 | Â | Â | .203 | 5.79 |

| Â | 80 | Â | Â | .276 | 7.66 |

| Â | 160 | Â | Â | .375 | 1 .01 |

| 3 | Â | 80 | 3.5 | .083 | 3.03 |

| Â | 10 | Â | Â | .12 | 4,34 |

| Â | Â | Â | Â | .141 | 5.06 |

| Â | Â | Â | Â | .172 | 6.11 |

| Â | 40 | Â | Â | .216 | 7.58 |

| Â | Â | Â | Â | .281 | 9.66 |

| Â | 80 | Â | Â | .3 | 1 .25 |

| Â | 160 | Â | Â | .438 | 14.32 |

| 3 1/2 | 5 | 90 | 4 | .083 | 3.48 |

| Â | 10 | Â | Â | .12 | 4.98 |

| Â | Â | Â | Â | .141 | 5.81 |

| Â | Â | Â | Â | .172 | 7.03 |

| Â | 40 | Â | Â | .226 | 9.11 |

| Â | Â | Â | Â | .281 | 11.16 |

| Â | 80 | Â | Â | .318 | 12.5 |

| 4 | 5 | 100 | 4.5 | .083 | 3.92 |

| Â | 10 | Â | Â | .12 | 5.62 |

| Â | Â | Â | Â | .141 | 6.56 |

| Â | Â | Â | Â | .172 | 7.95 |

| Â | Â | Â | Â | .203 | 9.32 |

| Â | 40 | Â | Â | .237 | 1 .79 |

| Â | Â | Â | Â | .281 | 12.66 |

| Â | 80 | Â | Â | .337 | 14.98 |

| Â | 160 | Â | Â | .531 | 22.51 |

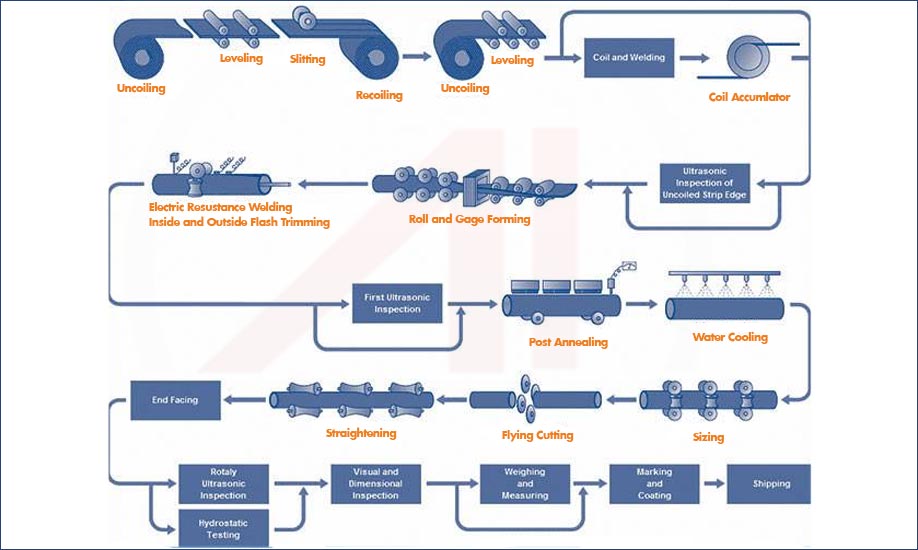

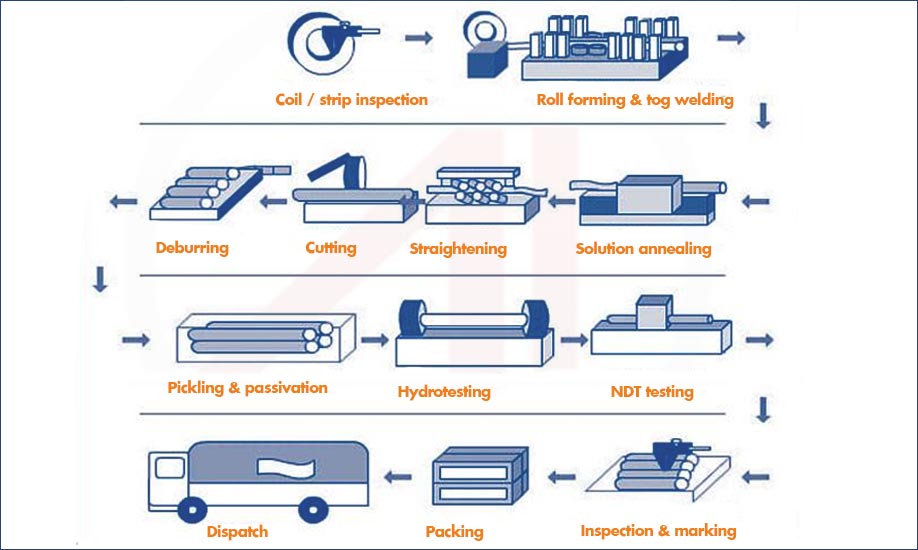

Seamless steel tube is extruded and drawn from a billet while welded tube is manufactured from a strip

The difference between the two tubes lies in their manufacturing processes. Seamless tubes do not have any weld seams, making them stronger and suitable for high-pressure conditions. On the other hand, welded tubes have welds, which make them less strong and suitable for medium to low-pressure applications.

Seamless Steel Tubes Manufacturing Process

Welded Steel Tube Manufacturing Process

Seamless Tubing vs DOM Tubing

| Description | Seamless Tube | DOM Tubing |

|---|---|---|

| Manufacturing Process | Made from a solid billet | Starts as a welded tube, then drawn over a mandrel |

| Advantages | High strength and durability | Good dimensional accuracy |

| Strength | Higher | Improved strength compared to standard welded tubes, but not as strong as seamless tubing |

| Weld Seams | No weld seams | Originally welded, but weld seam is removed during the mandrel process |

| Dimensional Accuracy | High | Very high |

| Surface Finish | Varies | Smooth and uniform after mandrel drawing |

| Cost | More | Less |

Seamless Steel Tube Uses

- Aerospace

- Oil and gas

- Structural components in demanding environments

- High-pressure hydraulic systems

Seamless annealed tubing is more expensive than welded round tubing

Seamless annealed tubing goes through several processes that make it costlier. The longer manufacturing process increases labor and machining costs, leading to a higher price.

Application for Welded Round Tubing

- General structural applications

- Piping and tubing in less demanding environments

- Automotive components

- Furniture and general manufacturing

Mechanical Properties of ERW vs Seamless Tube

| Property | Seamless Tubes | ERW Steel Tubes |

|---|---|---|

| Tensile Strength | Higher than welded | Lower than seamless |

| Yield Strength | Consistent across the entire tube | May vary |

| Elongation | Better | Can be reduced at the weld seam and heat-affected zones – HAZ |

| Impact Toughness | Higher | Lower |

| Fatigue Resistance | Higher | Lower |

| Hardness | Typically more consistent throughout the tube. | Show variation |

| Weld Integrity | N/A | Quality of the weld can impact overall mechanical properties |

Finish for Welded and Seamless Tubes

Seamless tubing

- Cold Drawn Finish

- Hot Finished

- Polishing

- Passivation

- Coating

Welded tubing

- Heat Treatment

- Descaling

- Polishing

- Coating

- Anodizing

Seamless Tube Weight Chart

| Nominal Tube Size | inch | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1.1/4 | 1.1/2 | 2 | 2.1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | 3 | 6 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| Outside Diameter | mm | 10.3 | 13.7 | 17.1 | 21.3 | 26.7 | 33.4 | 42.2 | 48.3 | 60.3 | 73 | 88.9 | 114.3 | 141.3 | 168.3 | 219.1 | 273.1 | 323.8 |

| Sched 5 S | Weight in kgm | 0.2 | 0.37 | 0.47 | 0.8 | 1.03 | 1.3 | 1.65 | 1.91 | 2.4 | 3.69 | 4.51 | 5.84 | 9.47 | 11.32 | 14.79 | 22.63 | 31.25 |

| WT in mm | 1.2 | 1.2 | 1.2 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 | 2.11 | 2.11 | 2.11 | 2.77 | 2.77 | 2.77 | 3.4 | 3.96 | |

| Sched 10 S | Weight in kgm | 0.28 | 0.49 | 0.63 | 1 | 1.28 | 2.09 | 2.7 | 3.11 | 3.93 | 5.26 | 6.45 | 8.36 | 11.57 | 13.84 | 19.96 | 27.78 | 36 |

| WT in mm | 1.24 | 1.65 | 1.65 | 2.11 | 2.11 | 2.77 | 2.77 | 2.77 | 2.77 | 3.05 | 3.05 | 3.05 | 3.4 | 3.4 | 3 Sportsground and Playground Machine Sportsground and Playground Machine is used to construct and maintance sports fields, playground, sports ground, rubber ground and Artificial Turf. Sportsground And Playground Machine,Playground Paving Machine,Rubber Paver Machine,Artificial Turf Maintenance Machine WUXI DEIICHEN MACHINERY PTY.,LTD , https://www.dicmachine.com |