Texo Case Study: Tank Inspection on an FPSO

Texo leverages the Elios drone to enhance efficiency, accuracy, and safety during oil tank inspections on FPSOs. Discover how this technology is transforming traditional methods and delivering real value.

Key Benefits at a Glance

|

Savings Traditional tank inspections require 4–5 rope access technicians who must wait until tanks are emptied and cleaned. The process typically takes 7–10 days, leading to high labor costs and production downtime. With Elios 3, Texo’s team of two can complete the same inspection in just 2 days per tank, significantly cutting both labor expenses and production loss. |

Speed Conventional inspections can take up to 10 days per tank, but Elios 3 reduces this to just 2 days. The ability to prioritize high-risk areas allows for faster identification of issues and more efficient maintenance planning. |

|

Safety Inspecting oil tanks using rope access involves significant risks—technicians work at height for extended periods. With Elios 3, pilots remain safely on the ground, eliminating exposure to confined spaces and hazardous environments. |

Operational Efficiency Using drones reduces the number of personnel needed, which helps operators save on crew space—especially important on FPSOs with limited onboard capacity. This frees up resources for other critical tasks. |

Introduction

Floating Production, Storage, and Offloading (FPSO) vessels play a crucial role in offshore oil operations by processing, storing, and offloading crude oil. These large platforms offer flexibility and can be relocated as needed, making them ideal for long-term field development. However, maintaining these vessels requires regular and thorough inspections due to their complex structure and high operational risk.

Typically, FPSOs have processing equipment above deck and storage tanks below. These vessels operate with crews of 50–70 people and require periodic inspections for safety and regulatory compliance. Traditional methods involve time-consuming and risky manual inspections, often requiring scaffolding or rope access teams.

Customer Needs

Texo, an inspection expert, was tasked with inspecting oil tanks on an FPSO. Inspecting these tanks while the vessel is in operation is challenging. Unlike dry dock scenarios where scaffolding can be easily set up, in-station inspections require careful planning and coordination. Tanks cannot be emptied simultaneously due to balance and operational needs, limiting the number available for inspection at any one time.

Traditional rope access methods are not only slow and costly but also pose serious safety risks. Scaffolding introduces additional hazards, including potential damage to tank coatings and dropped objects. Moreover, delays in identifying defects during inspections can lead to further downtime and increased repair costs.

Solution

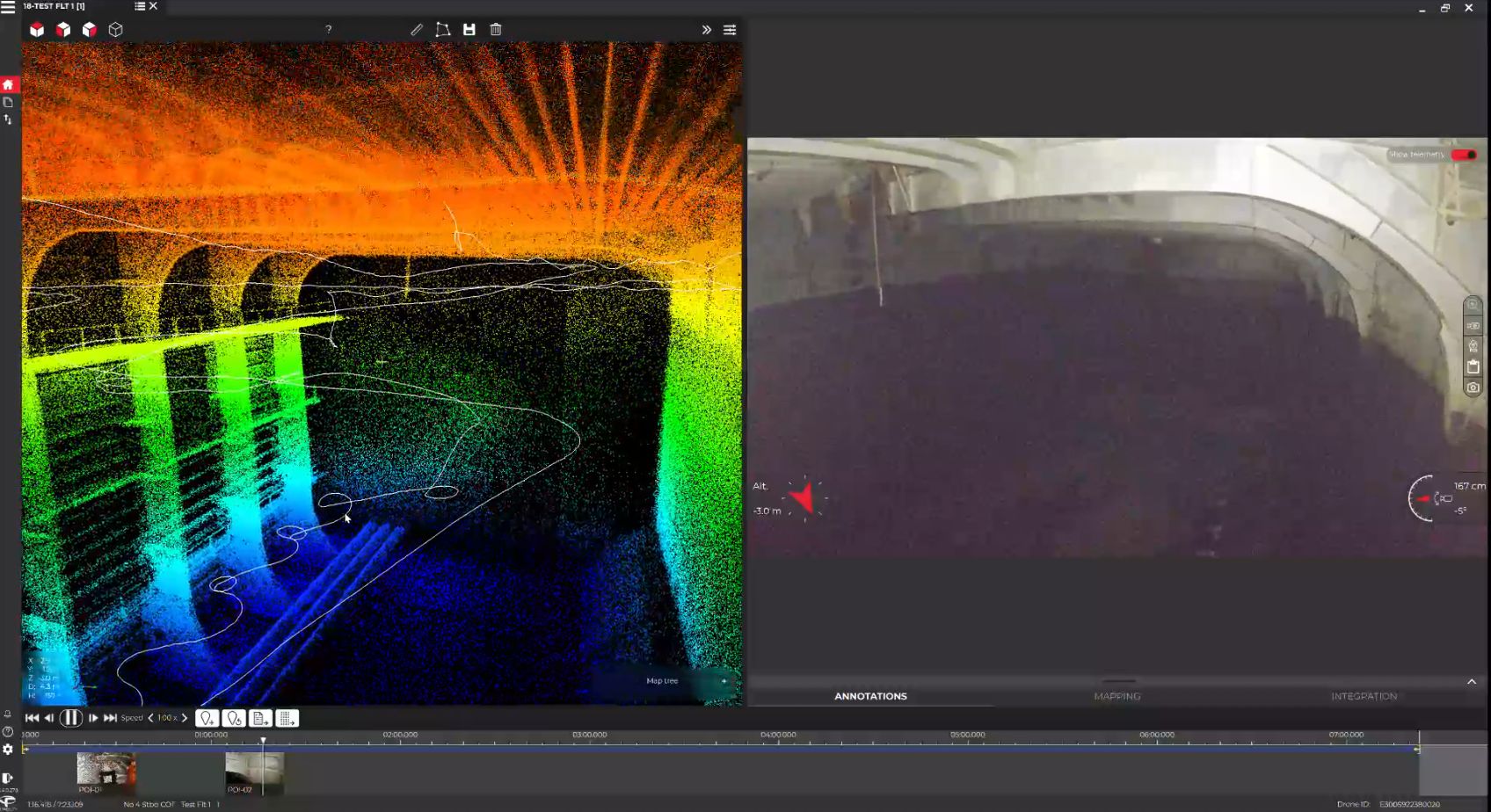

Texo deployed the Elios 3 drone to perform the inspection efficiently and safely. The team completed the task in just one week after tank cleaning, using only two personnel. The pilot remained outside the tank, ensuring no risk to human workers. Four flights were conducted to map the tank, generating a detailed 3D point cloud for analysis.

“Elios is such a game-changer,†said Xiang Wong from Texo. “It cuts down the number of people required and gives us confidence that the entire area has been thoroughly inspected.†The drone's flight path ensures full coverage, and the recorded data can be reviewed multiple times by different experts, adding layers of insight.

The Elios 3 also allowed Texo to identify high-risk areas first, enabling quicker decision-making and reducing overall downtime. For example, steam heating coils inside the tank are delicate and hard to inspect manually. The Elios 3’s collision-resistant design and 3D mapping capabilities made it easier to detect and analyze potential issues.

Results

Texo successfully completed the inspection in just 4 days, far faster than the usual 2-week timeframe. The client received accurate results, including detailed point cloud data that was previously unattainable. The feedback was overwhelmingly positive, and the client is now considering expanding the use of Elios 3 for future FPSO inspections.

The inspection was fully safe, with no risk to personnel. Onshore engineers also gained confidence in the completeness of the survey, knowing every part of the tank had been covered.

Conclusion

Texo has seen substantial value in using the Elios solution across various oil and gas projects. While the Elios 2 offered improvements over traditional methods, the Elios 3’s location referencing and point cloud capabilities make it even more powerful, especially when addressing identified issues.

Looking ahead, Texo plans to explore new applications, such as inspections on semi-submersible vessels. “These structures are like mazes,†says Xiang Wong. “The Elios 3 is perfect for navigating tight spaces without putting people at risk.â€

Texo Group is certified by DNV as an approved service provider for using Remote Inspection Techniques (UAVs) as an alternative to close-up surveys of ship structures and mobile offshore units.

Burr Grinder,Electric Burr Coffee Bean Grinders,Best Burr Coffee Grinder,Coffee Grinding Machine

Heshan Zilong Home Appliance Technology CO.Ltd , https://www.techonele.com